05 Mar Forklift Tires – Pneumatic and Cushion

When choosing the right forklift for your business operations, one critical decision is often overlooked – the choice of tires. Pneumatic and cushion tires are the two main types available, each with their unique features and benefits. Understanding the differences between these two options can considerably impact the performance, efficiency, and overall cost of your forklift. So, what is the difference between the two? Read on to find out which is the right solution for you.

Pneumatic Tires:

Pneumatic Tires:

If you operate your forklift primarily outdoors, on tougher surfaces, then pneumatic tires may be right for you. These tires excel in rough terrains. Their ability to absorb shocks and vibrations makes them ideal for heavy-duty applications such as construction sites, lumberyards, farms, and other outdoor environments. Deep treads and higher ground clearance provide a strong grip, excellent traction and stability when working with heavier loads and uneven operating surfaces. This enhances the forklift’s maneuverability. Pneumatic tires are generally larger than cushion tires and are more expensive. The cost is generally higher upfront because of their complexity but they may offer longer-term value in certain applications.

Pneumatic tires are either filled with air or solid rubber.

- Air Pneumatic tires are less expensive, but they are less durable and won’t last as long as solid tires. These tires are susceptible to punctures and leaks due to the air-filled design. They also require periodic maintenance and inflation checks.

- Solid Pneumatic tires are extremely durable and can’t be punctured by sharp objects. They are more durable, easily interchangeable and have a smoother ride. They do tend to last longer, which can make your forklift last longer. They are cost-effective and worth the extra money.

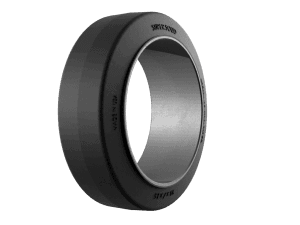

Cushion Tires:

Cushion Tires:

If you operate your forklift primarily indoors, or on smooth outdoor surfaces like concrete or asphalt, then cushion tires may be your solution. Cushion tires are made of solid rubber rings that get pressed onto a metal rim. They are molded to provide a cushioning effect, which eliminates the need for air, making them puncture resistant and less prone to flats. There are low maintenance requirements because they don’t need to be inflated. They sit much lower to the ground and can be either smooth or treaded. These tires have a small turning radius and are better at handling tight spaces and lighter loads. That is why they are typically used for indoor jobs like factories or warehouses or light outdoor usage on smooth concrete surfaces or mezzanines. They are less expensive to maintain and replace than pneumatic tires. They are durable when used correctly and very cost-efficient. Cushion tires are often more budget friendly. These tires are perfect for warehouse operations. Be aware that these tires create a harsher ride compared to pneumatic due to lack of air cushioning and there is less traction on uneven or rough surfaces.

In summary, the choice between pneumatic and cushion tires ultimately depends on the specific requirements of your material handling operations. Understanding the terrain, load capacities, and cost considerations will guide you toward the most suitable tire option for your forklift. If you are still unsure what will work best for you, let us help you make an informed decision for your specific needs.

Sorry, the comment form is closed at this time.